Extend structural lifetime with virtual inspection

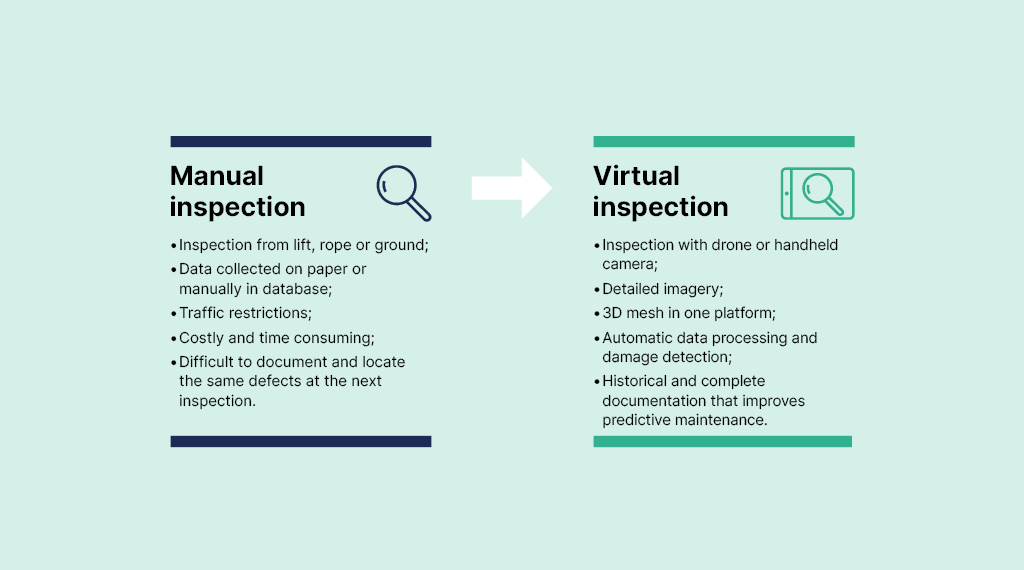

By moving from manual to virtual inspection of large structures, you can generate complete and historical data sets of your structure. Working as a baseline, this allows you to carry out predictive maintenance and solve issues up front, so you can extend the structural lifetime and cut costs as well as carbon emissions.

See how virtual inspection works

POSTPONE DECOMMISSIONING AND SAVE FINANCIAL AND NATURAL RESOURCES

The lifetime of large structures such as bridges, tunnels, and wind turbines depends on how good we are at maintaining them. If we can postpone decommissioning, we can save massive amounts of time and natural as well as financial resources.

With a Virtual Inspection platform drones and artificial intelligence are used to generate comprehensive digital data sets of any given structure and to detect deterioration. The data reveals the structural condition, enabling you to plan for and handle issues while they are still minor and easy as well as inexpensive to correct. By gathering all data in one platform, you can always access the full overview from any location and therefore perform your virtual inspections from the office.

ONE-STOP SOLUTION TO KEEP THE STRUCTURE HEALTHY

Several virtual inspection tools are available on the market. But for the investment to add value, it is important that the data capture software is paired with domain knowledge.

When defects are detected, you need a follow up plan that outlines when and where these must be attended to. That makes in-depth knowledge about structural deterioration crucial.

Learn more about our Virtual Inspection platform and our domain experts.

HOW IT WORKS

First, drones capture high-quality images of the entire surface of the structure, which are used to create a photorealistic 3D model. Using a combination of normal colour photography and thermographic images enables you to see “hidden” defects not always visible to the naked eye, like delaminated concrete or water seepage.

Next, the data is processed, and artificial intelligence is used to detect the defects.

Structural experts then qualify the defects that require repair or further follow up. All information is gathered in a web-based platform, where data can be shared or revisited at any time.