A transition rail connecting old and new railway. Digital tools and algorithms help us merge the maintenance planning on the old part and the new part.

EASY MAINTENANCE PLANNING USING LAM ALGORITHMS

11.05.2023

Using an algorithm-based linear asset management (LAM) system to maintain major infrastructure such as railways, roads, pipelines and power supply lines offers significant advantages – both economically and environmentally.

In this article, together with Simon Barthelemy, Railway Engineer in COWI’s international LAM team, we zoom into the track infrastructure area and how to implement an algorithm-based solution and its advantages.

What is LAM?

Many railway infrastructure managers have, to a greater or lesser extent, digitised their maintenance efforts using a LAM system. The system imports and processes the data collected along the railway lines, for example, track geometry quality, catenary wire position or inspection data in the form of manually observed defects.

“A LAM system stores, visualises and analyses data, after which the system can propose specific actions if configured to do so. Thus, the system can efficiently handle the collected data from the infrastructure,” explains Simon Barthelemy.

“LAM systems can be used at different levels – from basic to advanced use, where the built-in algorithms suggest specific maintenance actions. The usage of algorithms has a wide range of advantages, both from an economic and environmental perspective. But as an infrastructure manager, you must also be ready for a technology journey if you want to go to an advanced LAM usage.

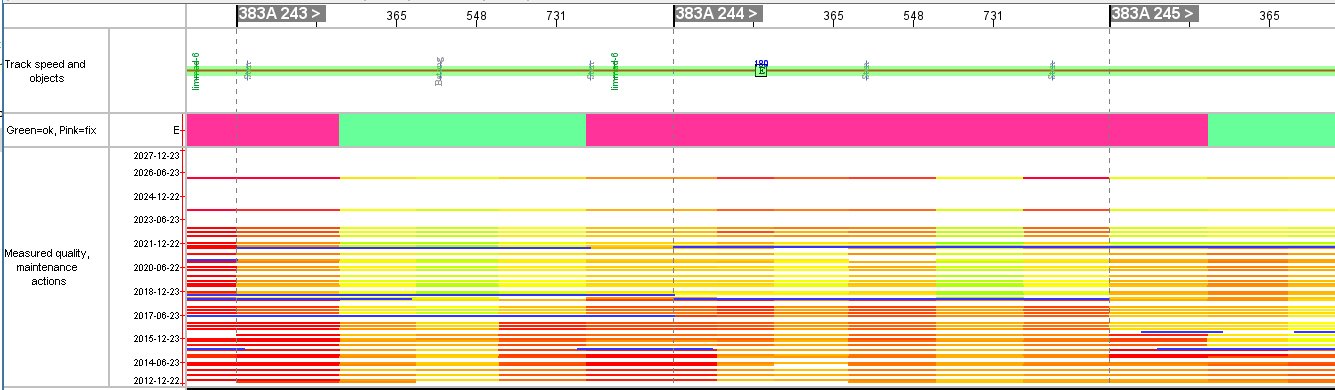

Example of a LAM system with measurements, old maintenance actions in blue and suggested new actions in pink.

The journey towards advanced use of LAM

If a LAM system has not been implemented, maintenance is typically based on data in PDF files or printouts, and data on previous measurements must be retrieved from the office or server. Consequently, it can be difficult to assess data, especially in complex networks such as railway stations with many tracks. Since it is difficult to compare several measurements, predicting the development over time is also difficult.

The basic use of a LAM system focuses on visualising data from exact locations on the track itself. The collected data is visualised, and the need for maintenance on a selected section or across the country can be analysed. It is also possible to implement simple analysis functions, visualise the average condition of track segments and identify exceedances of threshold values.

“The journey from basic to advanced use of a LAM system involves the implementation of algorithms that automatically analyse measurement data and suggest maintenance actions. The LAM system analyses every new measurement, and the algorithms suggest actions for the sections of the railway network that are part of the system,” says Simon Barthelemy. Here are some examples of maintenance actions which could be achieved from LAM algorithms:

- Track adjustments based on track geometry measurements

- Adjustment of catenary lines based on wear measurements

- Grinding and milling of rails based on wear, roughness and eddy current measurements.

Future LAM visualisation

Future LAM visualisation

HOW THE ALGORITHMS ARE CREATED

In order to create the algorithms needed, it is necessary to transfer the infrastructure manager’s knowledge, manual rules and routines to the LAM system. Together with a software developer, the infrastructure manager writes down the steps and criteria they usually use when planning maintenance activities. It could look like the following:

- If the parameter P1 exceeds the threshold value Thigh along at least a length of L1, maintenance action A1 is carried out.

- However, if the parameter P2 exceeds the threshold value Tlow, maintenance action A2 is carried out instead.

- If the exceedance occurs in, for example, a sharp curve, the working area is changed, and the entire curve is included.

If minor issues are nearby (exceedances of the threshold value Tlow), these issues should be solved using personnel and machines in the area, thereby avoiding spot-wise actions and unnecessary transport.

Each algorithm contains a physical model of how the object will behave with or without maintenance actions. An example:

- Rail wear increases by 0.8 mm per year.

- Without maintenance, it will lead to unsafe conditions after three years.

- A maintenance action will extend the service life by five years.

Threshold values and conditions may be adjusted to the circumstances, for example:

- Age of the assets: New assets have a higher tolerance than older assets.

- Functionality of the assets: The thresholds depend on the permitted train speed.

- Use of the assets: The thresholds may depend on, among other things, the annual rail tonnage.

Once an algorithm is described, it can be implemented as an analysis function in the LAM system. Data are then loaded, and the desired maintenance action is saved as an object in the system.

Developing and implementing algorithms

You cannot and should not expect the first version of the algorithm to be the final one. A LAM system cannot stand alone, and, especially at the beginning, some of the actions suggested by the algorithm might seem inappropriate. Therefore, practical human experience is important, and the next step for the infrastructure manager and the software developer should be to:

- Identify poor suggestions and examine why they were suggested.

- Adjust the criteria to ensure better suggestions in these cases.

- Run the new version of the algorithm to see if the suggested actions improve and look for new poor suggestions, after which you go back to the first of these three bullet points.

The algorithm will be considered sufficiently reliable at some point, and then it is time to release it in the LAM system. Now the organisation can use the maintenance actions suggested by the system. Simon Barthelemy emphasises that the infrastructure manager still plays an essential role in contributing human experience and insight. The algorithm-based suggestions can be assessed based on two reliability levels:

- 1: The infrastructure manager carries out their own maintenance planning while considering the algorithms’ suggestions as inspiration.

- 2: The infrastructure manager takes the system’s suggestions as a starting point, reviews them and makes changes based on their experience with the system.

Railway joint

Railway joint

THE MANY BENEFITS OF ALGORITHMS

In order to reap the benefits associated with using an algorithm-based LAM system, it must be ensured that the algorithms are designed so that maintenance of, for example, track sections is done in the most cost-effective way while also extending the service life to the greatest extent possible. It benefits the economy and the degree of sustainability and goes hand in hand with service life.

“This is where LAM really starts to pay off – when you can prevent expensive maintenance of severe defects that disrupt traffic, extend the service life by waiting as long as is reasonable to replace the assets and even reduce the amount of manual work,” concludes Simon Barthelemy.

“At the same time, you can drastically reduce the time spent reviewing data. The LAM system analyses large amounts of data in a short time, allowing the maintenance planner to focus on verifying the algorithms’ suggestions. Finally, the algorithms’ suggestions are objective and solely based on data. Therefore, you are more independent of people with specialist knowledge making the decisions and less vulnerable if someone changes job or retires because their valuable knowledge is preserved in the algorithms.”

COWI’s LAM team can, for example, support infrastructure managers in cooperation with data providers and software developers.

MEET THE EXPERT

Simon Barthelemy holds a master’s degree in engineering physics, focusing on mechanics and programming. Simon has 13 years’ experience in analysing railway condition data establishing algorithms, visualisations and new ways of planning maintenance. He has created and implemented an algorithm for planning the tamping in the Swedish Transport Administration, ensuring that tracks remain non-bumpy at a low cost. He has also developed algorithms for the milling, grinding and replacement of rail to ensure low levels of wear and damage in the rail running surface. His key experience also includes measurements of ballast profile, jointed tracks and connecting the LAM system with a map and the driver’s view images. In COWI, Simon is a consulting expert focusing on the application of LAM systems and data-driven railway maintenance.

Get in contact

Simon Barthelemy

Railway Engineer

Transport and Urban Development, Norway