NEW PLATFORM OPTIMIZES THE LEVELIZED COST OF E-HYDROGEN and E-FUELS

04.05.2023

Today, the speed of realized e-fuel facilities and projects needs to go up if we are to decarbonize hard-to-abate sectors and enable the green transition in due time. The problem often pertains to the numerous techno-economic parameters making decisions for giga-scale projects high-risk. A new model that makes early stage technoeconomic assessments to minimize the levelized cost of e-fuels and financial risks is gaining ground in the market.

High risk decision-making stalls giga-scale projects

The global market for sustainable energy solutions is propelling to new heights. As a result, the demand for hydrogen (H2) by 2030 is expected to reach 180 Mt/year. Assuming a quarter of this H2 comes from water electrolysis, and most of the current and close future projects consisting of merely a few hundred MW and rarely going to GW scale, we need to realize 300-500 green H2 projects globally.

Right now, there are more than 500 announced projects in the world, but with a current Final Investment Decision (FID) passed rate of around only 5%, the number of projects expected to be realized is very low. Too many techno-economic parameters make FIDs risky. Examples include striking the right balance between installed capacities of wind-solar-battery and the electrolysis capacity as well as the product storage capacity. To add more complexity to the challenge, consider access to renewable grid power with variable purchase and curtailment prices. Add hereto scenarios with green methanol or Sustainable Aviation Fuel (SAF) where biogenic CO2 needs to be imported or captured or if biomass power generation or gasification is also included in the project.

The problem consists of a set of multivariable equations with more unknowns than the number of equations. In essence, we are dealing with an optimization problem with a set of constraints and an objective function, which needs to be minimized for levelized cost of hydrogen or green fuel.

Accordingly, an early stage technoeconomic assessment using reliable models is essential to minimize the projects’ financial risks.

Early-stage techno-economic optimization

Last year, a new techno-economic modelling platform was introduced to the market to increase the rate of FID-passed projects and decrease the development cost. The platform will optimize the dimensioning of more than 20 value chain components from renewable energy capacities over energy storage to final product synthesis and distillation to determine the ideal system configuration for green fuel production with minimal levelized cost of fuel. The results enable decision makers to de-risk the project investment and develop the most technically and financially viable projects.

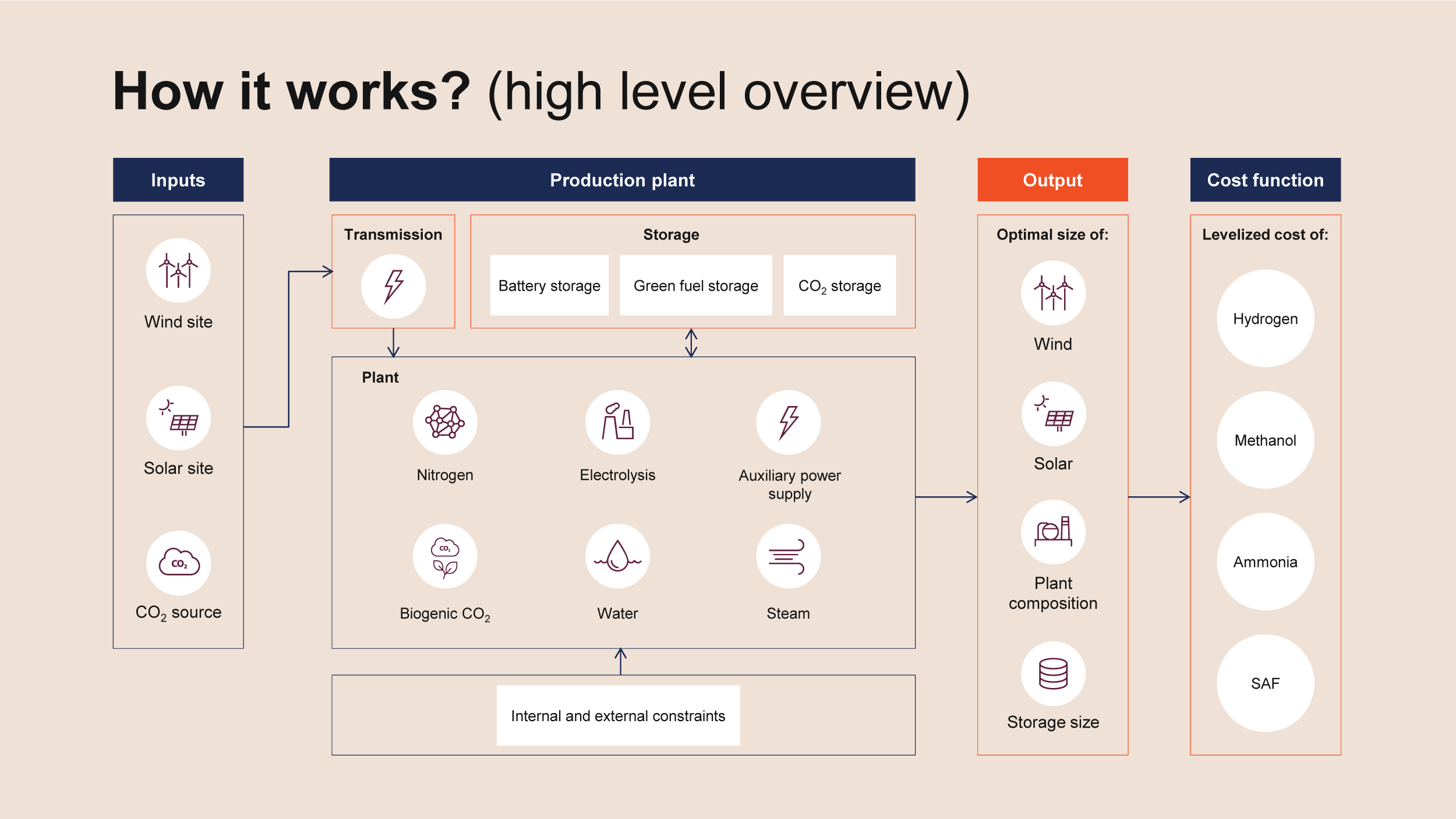

Inputs to the model consist of renewable power profiles and CO2-sourcing as either provided by the customer or based on our estimates. The objective function or cost function is the levelized cost of green fuels like methanol, ammonia, hydrogen and SAF, which needs to be minimized . Feasible solutions must adhere to all external and internal constraints imposed on the model, such as regulatory constraints to achieve certifiable fuels (external) and technical constraints on operational limits (internal).

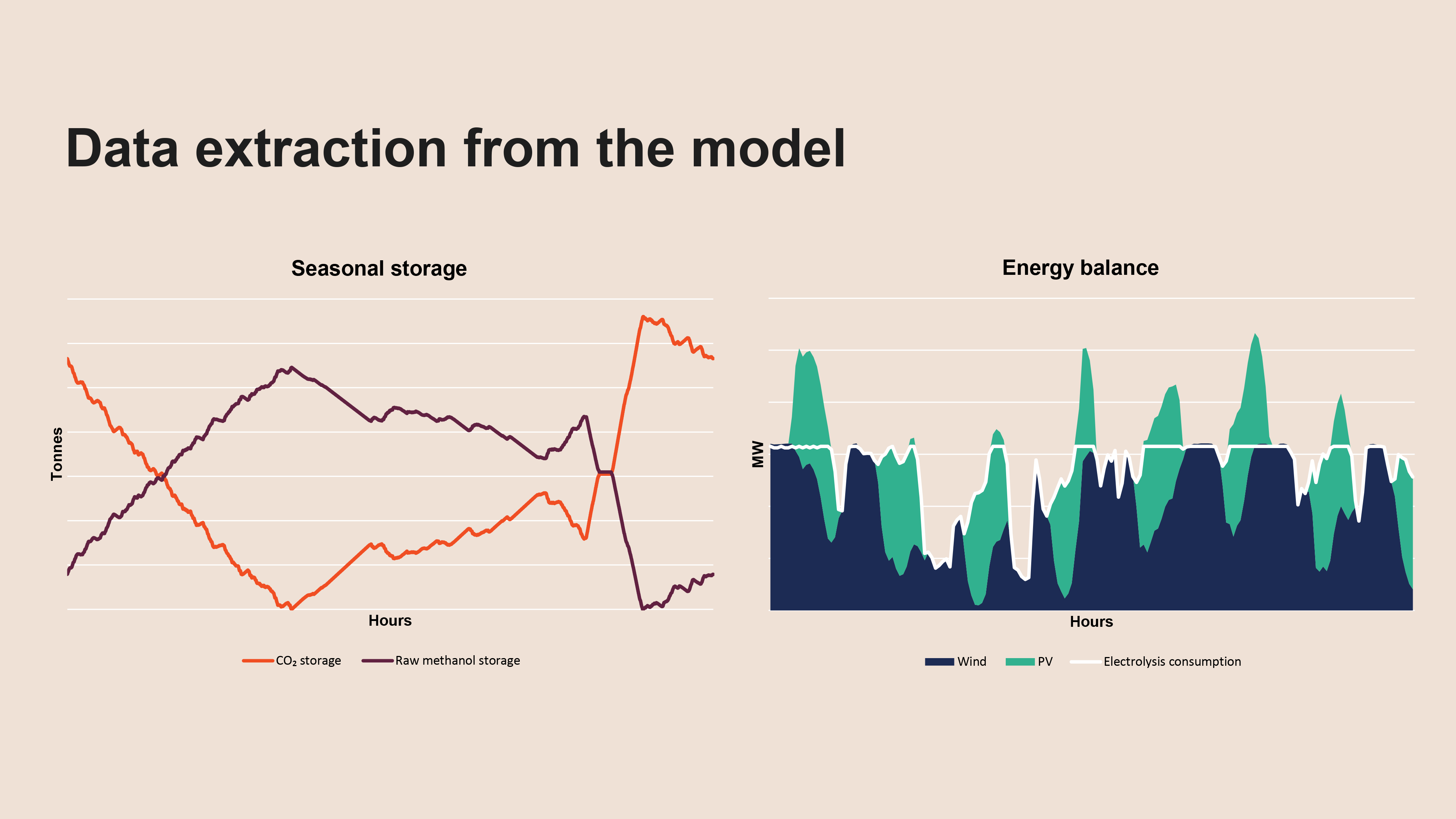

Once the model is optimized it provides valuable information on for example the variation of seasonal storage for feed and product, specifically carbon dioxide as feed and raw methanol as product. It quantitively shows how, the storage of e.g. CO2 change, depending on the variation on the input from both wind, solar and CO2-source. This allows the project to minimize the cost of storage facilities.

The optimized solar and wind capacity for a specific hydrogen production demand is suggested based on the hourly solar and wind power variation input. The model also calculates the revenue from an optimized curtailment strategy.

The model furthermore considers other constraints related to the plant site and renewables sites, such as land footprint, grid connection, and transmission cost. Wind and solar renewables are land intensive technologies and there may be limited availability of suitable land. Similarly, the project site selection may also significantly impact transmission and transportation cost.

Optimized capacities for the entire value chain

Apart from the levelized cost of green fuel as an output of the model, the optimized capacities for the whole value chain are reported. In a multi-purpose green fuel production site, for example for methanol and ammonia, the model identifies the capacity for mixed renewable power, battery storage, methanol, ammonia plant capacity, and more.

It shows the breakdown of the levelized cost of green fuel of the entire value chain by listing the contribution of each step from renewable power generation to transmission, electrolysis and storage, chemical synthesis, and transportation.

Live since the beginning of 2022

While the platform is not a traditional piece of software, it is a tool that provides a basis for solid decision making when undertaking large-scale green fuel and chemical projects. Within a year from introduction, it has been used in projects in several countries. The model is continuously updated and validated with all new features peer reviewed by third party experts before use.

Get in contact

Jeppe Grue

Technical director

Green Fuels & Energy, Denmark

Tel:

+45 56408734

jegr@cowi.com

Get in contact

Morten Hørmann

Principal Economist

Society, Economics and Environment, Denmark

Tel:

+45 56402070

mho@cowi.com